Products

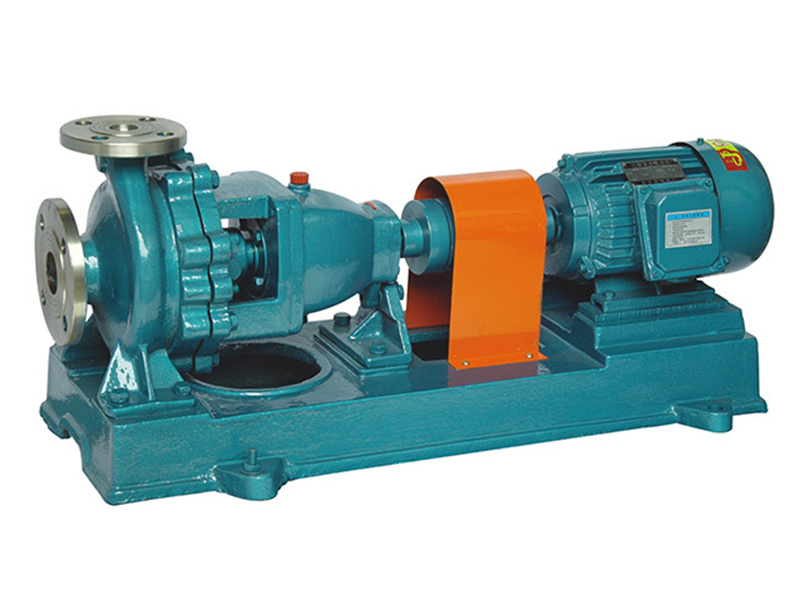

ES series environmental protection maintenance-free double suction split centrifugal pump

Key words:

Category:

Single stage pump

E-mail:

ES series environmental protection maintenance-free double suction split centrifugal pump

1. Product overview

ES series environmental protection maintenance-free single-stage double-suction mid-opening horizontal and vertical centrifugal pumps are created by the company's experts and domestic and foreign experts on the basis of summarizing years of experience in the manufacture and application of double-suction pumps, combined with the pain points of users in the process of using pumps. A new type of water pump (horizontal pump patent number: ZL 2018 2 2092944.2; vertical pump patent number: ZL 2019 2 0293130.7). Its main features are environmental protection and maintenance-free.

1.1 Main advantages

Adapt to the new era of environmental protection

The traditional grease-lubricated rolling bearings (including the original traditional sliding bearings) are cancelled and no longer used, and the self-lubricating bearings are used instead, the traditional oil-lubricated bearings are banned, and the pollution of oil products to the environment and media is removed.

Adapt to the new era of energy conservation

A. Lubricating oil is no longer used:

B. Reduction in the use of materials:

1. Remove the bearing body for traditional pumps;

2. Shorten the pump shaft and remove a mechanical seal:

C. Improvement of efficiency:

1. Optimization and improvement of hydraulic model:

2. Changes in structure and lubrication methods bring about improved efficiency. Maintenance-free and reduced operating costs:

1. The bearing is maintenance-free, eliminating the need for manual inspection;

2. The non-driven end seal adopts a static seal, which reduces the number of mechanical seals.

Longer bearing life

The service life of traditional ball bearings is about 2-5 years according to the application environment and working conditions. With this product, the service life of the bearing can reach 5-10 years. The operation is safer, more stable and more reliable

A. It adopts a careful design to reduce vibration and noise;

B. The non-drive end adopts a static seal, which reduces one failure point;

C. The bearing frame of the traditional double suction pump is removed, the length of the pump shaft is shortened, the overall stability of the pump is higher, and the operation is more stable.

D. All series of pumps use diaphragm coupling;

Expansion of application fields

According to different uses, choose to use a variety of material combinations, which can be used in a wider range.

Prev

ISG type vertical single-stage centrifugal pump/IGR type hot water pump/IGY type light oil pump/IL type vertical single-stage centrifugal pump

Get a free product quote