Products

QW type submersible sewage pump

Key words:

Category:

QW type submersible sewage pump

E-mail:

QW type submersible sewage pump

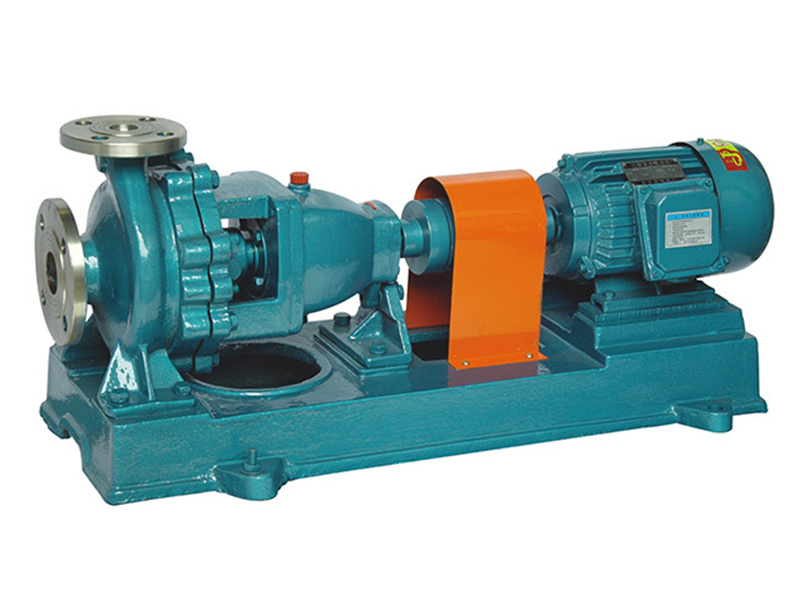

OW submersible sewage pump is a new product jointly developed with Jiangsu University on the basis of absorbing the advanced experience of foreign congeneric products. The product adopts the patented technology of double sealing chamber invented by Professor Zhu of Jiangsu University, which makes the sealing more reliable and the use of the product safer. The impeller adopts a double-channel design structure, which is anti-blocking and anti-winding, has strong balance ability and stable operation, which greatly improves the ability of dirt to pass through, and can effectively pass through solid particles with a diameter of about 50% of the pump diameter. Combined with the superb production and processing technology of the company, the comprehensive technical indicators of the product are in the leading position in China and have reached the advanced level of international congeneric products.

This type of pump can install various protection devices according to user requirements, such as wiring cavity water leakage detection protection, stator and bearing temperature rise protection, oil chamber water leakage protection, motor cavity water leakage protection, etc., to improve the safety of the electric pump.

The motor power ≥ 11kW adopts the domestic circulation self-cooling system. The use of medium to cool the motor is safe and reliable.

Using the latest carefully developed mechanical seal, it is safer and more reliable to use, and its service life can reach more than 8,000 hours.

Various installation forms: double guide rails can be used for automatic coupling installation, mobile installation, etc. When the automatic coupling installation is adopted, the outlet pipe seat is fixed at the bottom of the pump pit. When the pump is lowered along the guide rod, it is automatically engaged with the outlet pipe seat, and when it is lifted, it is automatically loosened. When the mobile installation is adopted, the pump can be directly put into the water, and is connected to the pump body with a hose or hard pipe, and the pump can be easily transferred to different construction sites.

Equipped with sewage pump water level control system according to user needs. According to the change of water level, the start and stop of the unit is automatically controlled, and the standby pump runs in time. In the double-pump pumping station, the two pumps are rotated to achieve the balance of pump wear and maintain the economical operation of the interval time, etc., to achieve automatic management.

According to the needs of the user, the pump can be started directly, star-triangle line start, automatic pressure regulation start and other different start methods.

According to the needs of users, impellers and other flow components can be made of ordinary materials or high wear resistance and corrosion resistance materials.

According to user needs, an automatic stirring device can be installed, and its sewage discharge performance is better, especially suitable for high-concentration sewage occasions.

This pump is used for domestic sewage discharge; sewage treatment systems such as high-rise buildings, industrial and mining enterprises, municipal engineering, etc.; urban environmental protection, sewage interruption, sewage treatment; food, medical, commercial systems and other sewage discharge.

The pump flow range: 7~ 8600m2/h; lift range: 3~ 80m; rated speed: 740~ -2900r/min; system pressure: ≤ 1.0MPa; medium temperature -15~ 60C; medium pH value range: 4~ 10; medium density: ≤ 1.3x 10kg/m *: motor protection class IP68; motor insulation class F; the number of launchs per hour is not more than 6 times, and the interval is uniform; the maximum diving depth is 20m; direction of rotation: The pump rotates clockwise when viewed from the motor end.

Prev

None

Next

Get a free product quote